Oil & Gas

Steam injection is an increasingly common method of extracting heavy crude oil. It is considered an enhanced oil recovery (EOR) method and is the main type of thermal stimulation of oil reservoirs. There are several different forms of the technology, with the two main ones being Cyclic Steam Stimulation and Steam Flooding.

Discover more

Animal Feed

A good pellet system of animal feeds needs to have a regulated supply of steam, which is essential to a good pelleting operation. In fact, it doesn’t matter what kind of conditioner you have if the quality of steam is poor. Steam conditioning is a very important element in achieving high quality pellets and elevating production rates at a low cost. The use of steam can increase the production of a pellet mill in almost all feeds.

Discover more

Beverages

Beverage production involves many energy-intensive processes. As well as electricity, heating energy and cooling, process heat in the form of steam and hot water is essential for ensuring the maximum quality of the products and for adhering to the strict regulations for food safety. That's why Clayton offers Steam solutions which are exceptionally reliable, consistently energy-efficient and operate automated.

Discover more

Breweries

In breweries, steam plays a crucial role in maintaining high sanitation levels, cleaning brewing utensils and hard-to-reach areas, and ensuring beer flavours remain consistent. For example, many breweries use steam generators to boil wort, which is a highly energy intensive step in the overall brewing process.

Discover more

Distillery

One of the most important features for any distillery is a steam generator. Steam is what allows distilleries to put the finishing touches on their products. Not only is the volume of steam important depending on how big or small a batch is, but the quality of steam is also essential to the distilling process. Clean high-quality steam is needed to ensure the taste and flavour of the spirits is exactly what the distillery intends it to be.

Discover more

Food Industry

Food production involves many energy-intensive processes. As well as electricity, heating energy and cooling, process heat in the form of steam and hot water is essential for ensuring the maximum quality of the product and for adhering to the strict regulations for food safety. That's why Clayton offers steam solutions that are exceptionally reliable, consistently energy-efficient and that carry out automated operations.

Discover more

Marine & Offshore

In the Marine industry, the introduction and development of innovative solutions represents a crucial challenge to optimise the different heating requirements found in this industry sector. The need for innovation is present throughout the entire value chain, from the design stage to the completion of the vessels. Our multi-purpose generators are available in a wide range of capacities. Clayton Steam Boilers perform numerous important functions, such as heating work floors, desalination , de-icing, etc.

Discover more

Chemical Industry

The chemical and pharmaceutical sector includes the manufacturing of chemical synthesis products such as pharmaceutical products (medication), oleo-chemical (food, cosmetic) and products related to the manufacturing of polymers (rubber, glue, paint etc.) In this sector both continuous and batch operations are common. Batch operations in particular can involve large variations in heat load, from initial large surge demand to end of batch temperature maintenance. When using steam, this gives wide variations in the steam demand which can be served by responsive and flexible steam generators such as those manufactured by Clayton.

Discover more

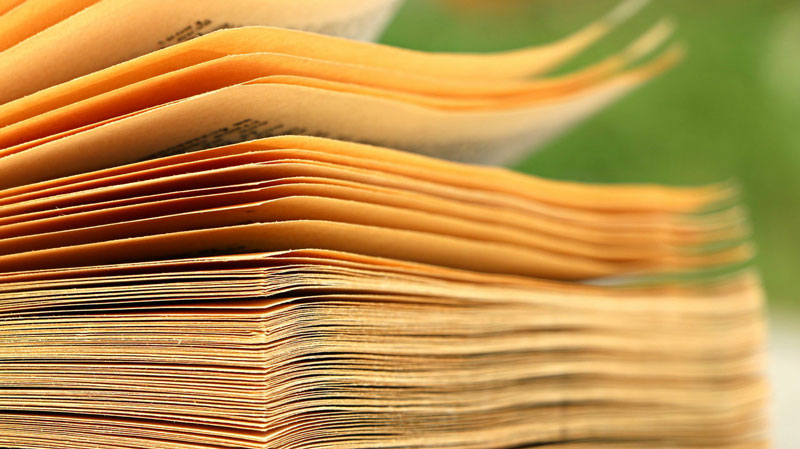

Paper Industry

Hot water, steam and electricity are used for thermal pulping and treatment processes as well as heating the cylinders for pressing, transporting and drying the paper rolls. Paper mills and corrugated packaging plants use rolls that are internally heated with steam. Maintaining a uniform temperature across the surface of the roll is essential for making quality products. Since steam is a gas, it fills the entire volume of the roll and evenly distributes heat as it condenses.

Discover more

Pharmaceutical Industry

The Pharmaceutical sector includes the manufacturing of chemical synthesis products such as pharmaceutical products (medication), oleo-chemical products (food, cosmetic) and products related to the manufacturing of polymers (rubber, glue, paint etc.) In this sector both continuous and batch operations are common.

Discover more

Power Plants

Providing a stable supply of energy around the clock, offering competitive prices, adhering to legal guidelines and reducing environmental impact are some of the challenges faced by energy suppliers. Clayton offers support with highly reliable, flexible and innovative energy systems. Our steam boilers start up steam turbines and can be used as an emergency supply for district heating grids of large gas and steam turbine power plants.

Discover more

Textile Industry

Steam is used for dying, washing, cleaning, drying, pressing and folding in the textile production process and in laundries. Both for steaming as a textile finishing process as well as for distilling solvents.

Discover more